Explore the VitroJet Solution

Control and reproducibility of your samples for cryo-EM

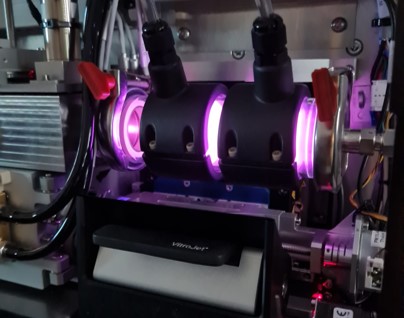

The VitroJet is the most innovative solution today to vitrify your samples for cryo-EM: Its technology allows any scientist interested in structural biology to take the next step in sample preparation highly controlled and reproducible. The VitroJet is very flexible allowing any grid type as long as it is a preclipped autogrid. This facilitates the preparation of your transmission electron microscope containing an autoloader. The VitroJet offers a fully automated workflow which makes it easy to switch users, and an embedded glow discharger ensuring consistent wettability. The unique pin printing technology with 12 pins allows deposition layers in the nanometer scale, and the jet vitrification technology ensures superior cooling rates. The integrated high-end camera assists you during the sample preparation process for visual validation. Altogether, this makes the VitroJet the most innovative solution to vitrify your samples for cryo-EM in a controlled and reproducible way. Having a handle over your grid preparation enables scientists to reach results faster. In this way unraveling the mysteries of proteins for the development of life-changing medicines, vaccines, and cures for diseases.

Watch the VitroJet in action

Our technology

Your benefits

The VitroJet integrates all the below technology into one solution suitable for every cryo-EM lab. Altogether, this makes the VitroJet the most innovative solution to vitrify your samples for cryo-EM controlled and reproducible. Having a handle over your grid preparation enables scientists to reach results faster.

Preclipped autogrids for any microscope autoloader equipped cryo-TEM

Autogrids clipped at room temperature makes for less required training and fine handling skills. No more clipping under liquid nitrogen! The pre-clipped autogrids allow you to image on any cryo-transmission electron microscope containing an autoloader. After the pre-clipping and introducing your grids to the system grids are handled automatically within the workflow. After the pre-clipping no user interference is needed thanks to the automated grid handling.

Automated workflows for user independence

Integrated features in the preparation workflow, such as the plasma treatment and automatic grid handling, makes the sample preparation on the VitroJet highly reproducible and user independent. Following the preparation of the machine and pre-clipping of autogrids, the grid preparation process takes place with minimal user interference. This elimination of manual steps such as post-clipping limits damage and contamination of the vitrified samples. During the sample preparation process you can set, adjust and store relevant parameters. Through automation you can standardize your process and reload relevant protocols saving time and controlling your workflows increasing your sample preparation efficiency.

Embedded glow discharger for consistent wettability

The embedded glow discharger provides a tunable and consistent method for enhancing wettability of the grid. Glow discharge time is controllable, designed for protocol flexibility and consistency.

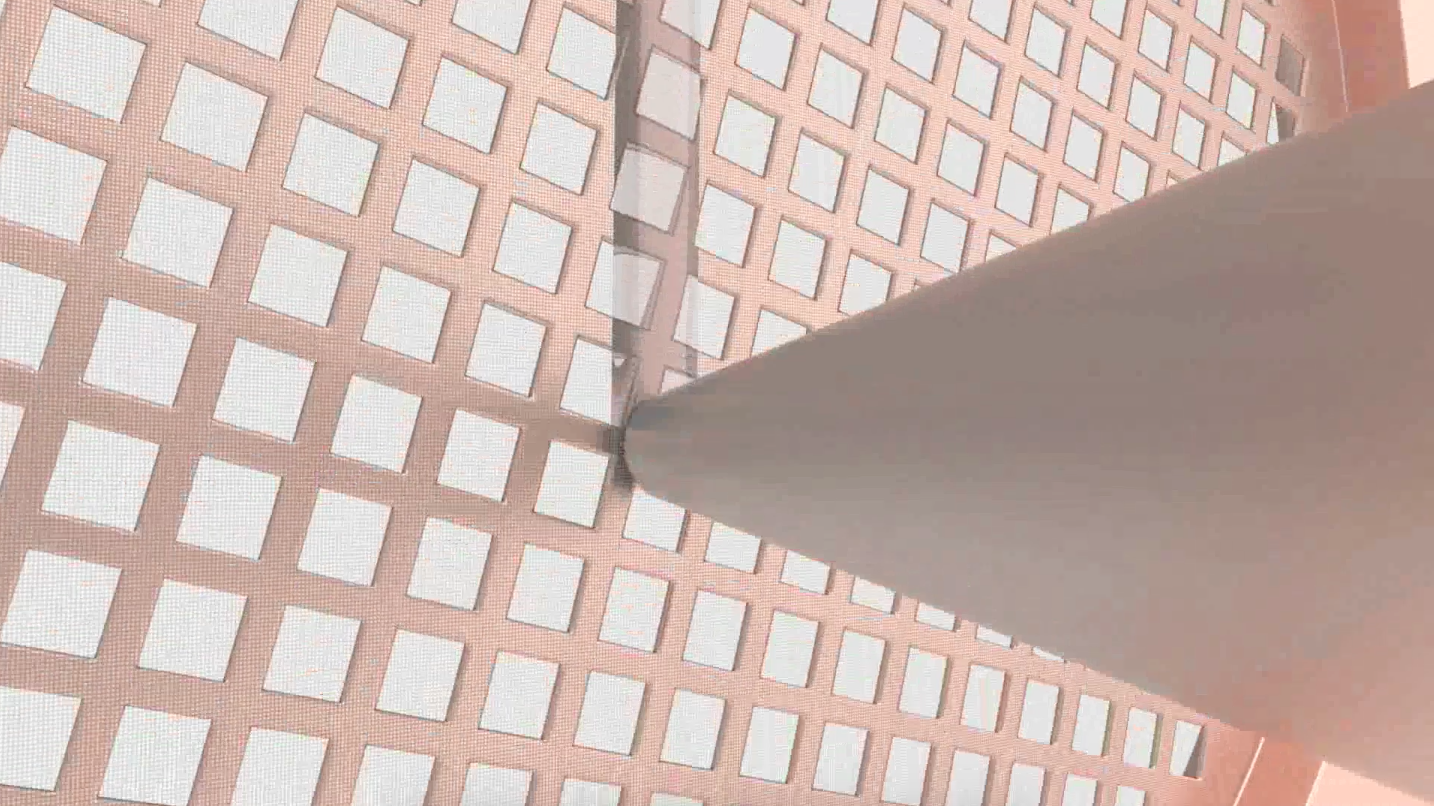

Pin-printing for nanometer deposition precision

The unique pin-printing technology of the VitroJet controls thin layer deposition using sub-nanoliter sample volume. The sample is deposited with nanometer precision. The layer thickness can be varied by adjusting the parameters, such as writing velocity and distance between pin and grid. Dewpoint control ensures minimal evaporation and condensation. Hereby you circumvent blotting which reducing potential damage to sample or carrier.

Visual feedback for sample validation

The integrated high-resolution camera enables visualization of the entire sample deposition process. It allows you to monitor the success of the deposition at all times. The high quality is validated prior to microscope screening. And this way you can achieve research results faster. You can log videos, images, and settings to document, revisit and reuse or revise.

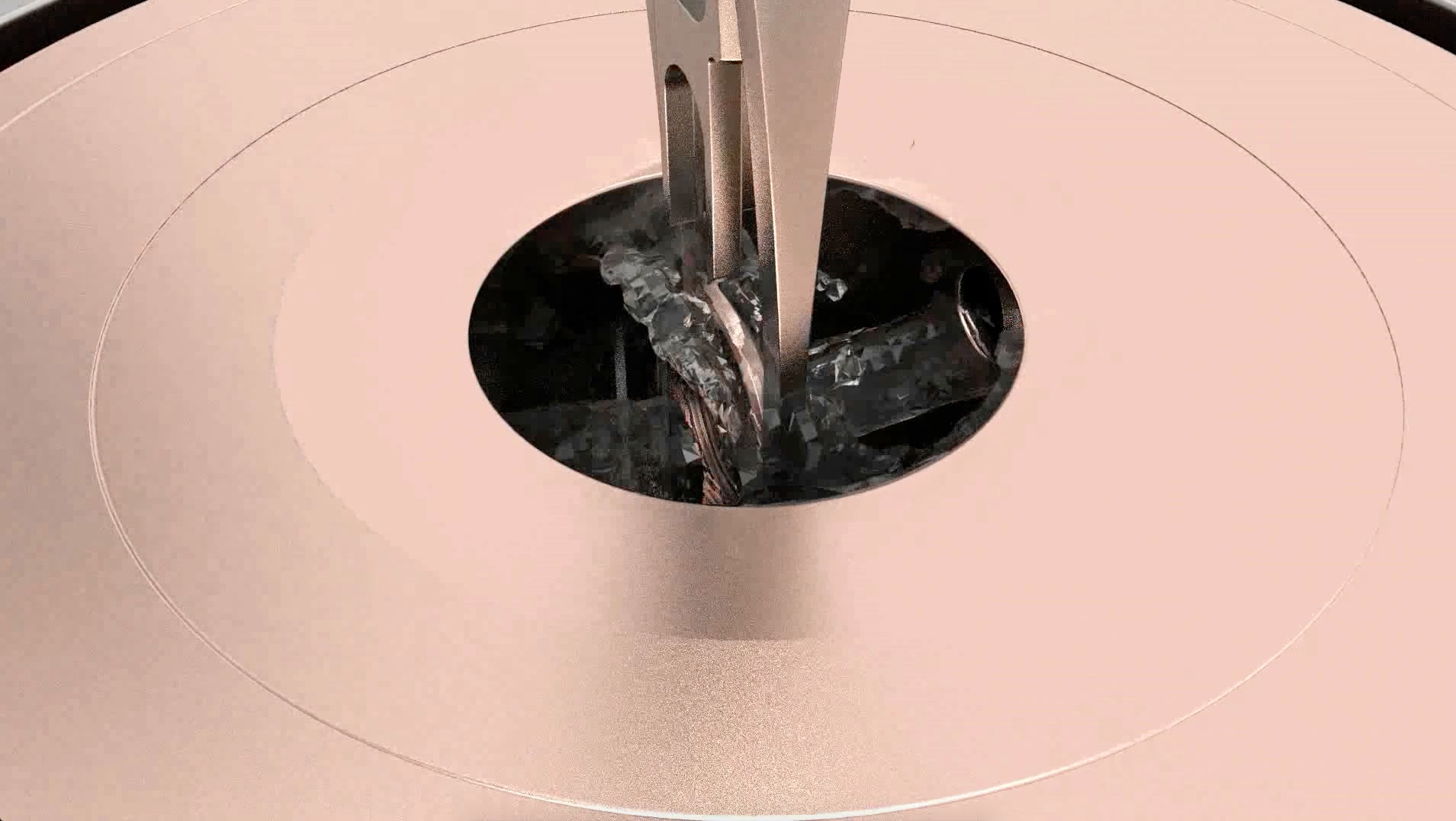

Jet vitrification for superior cooling rates

Jet vitrification cools the sample starting in the center of the grid, ensuring vitrification of the sample first rather than the grid first, as is done in plunge freezing. Furthermore, it enables vitrification of autogrids due to the high cooling rates.